Suburban Plumbing Blog

Plumbing Articles from Orange County, CA.

Your Ultimate Guide to Gas Pressure Testing

Over 62 million US homes are heated using natural gas. As its popularity increases, the demand for professionals to manage it does as well.

Plumbing and HVAC services are knowledgable about a variety of factors that may affect your home. One of the most important is gas pressure.

If a gas line experiences too much pressure, it could suffer severe damage and/or leaks. Gas pressure testing serves as a method of ensuring that the line can stand up to high levels of force.

Read our guide to learn all you need to know about gas, including how to test its pressure levels.

Gases Explained

Gases are a complex state of matter that can be difficult to understand. Several laws and equations make the process easier.

Understanding gas is especially important for those who use it in their homes. They should know the different types of gases as well as the related laws and the variables their equations measure.

Types of Gases

There are several examples of gases, from nitrogen and oxygen to helium and carbon dioxide. They are two types; ideal and real.

Ideal gases follow the kinetic-molecular theory exactly at all levels of temperature and pressure. To do so, their molecules must occupy zero volume with no attractive forces bringing them together.

All gases technically fit into the real category, because they can never completely follow the kinetic-molecular theory. Fortunately, proper laboratory conditions can make them behave almost exactly like an ideal gas.

Gases face different levels of temperature and pressure. Which conditions make a real gas behave like an ideal gas? The higher the temperature and the lower the pressure, the more ideal a gas will become.

Gas Laws

The ideal gas law is written as PV=nRT. It’s used to determine how a gas relates to its environment.

All other gas laws are simple gas laws. They include Boyle’s, Charles’, Avogadro’s, and Amontons’ Law.

Boyle’s Law describes how the pressure and temperature of a gas relate when the temperature and amount of gas remain constant.

Charles’ Law describes the relationship between volume and temperature when the amount of gas and pressure remains constant.

Avogadro’s Law shows how the volume and amount of gas relate when temperature and pressure remain constant.

Amontons’ Law shows how pressure and temperature relate when the amount and volume of the gas remain constant.

All of these laws and equations make it easier for professionals to measure and manage gas lines. They can use the equations to measure each variable and see which ones may be causing issues.

Variables

Five variables determine the condition of a gas; pressure, volume, temperature, the amount of gas, and a gas constant written as the letter R. Temperature is measured in Kelvin, and the amount of gas is measured in moles.

Each of these variables affects gas pressure. More moles of gas and higher temperatures cause it to increase. Decreasing gas volume has the same effect.

Volume, temperature, and amount of gas may decrease the pressure of a gas in a closed container. Remember that all the previous effects also work in reverse. Increasing temperature, moles of gas, or gas volume decreases gas pressure.

Becoming familiar with your plumbing system helps you maintain it properly and know when you need to call in a professional for help. Check here for more plumbing terminology you need to know.

How Gas Pressure Testing Works

Professionals who test gas lines must be completely familiar with the process and all of its components. It’s also helpful for you to know more about your gas line to understand how to maintain it and what workers will do to it when you call them.

There are several things to know about gas pressure testing. Some of the most important include the process used, the different types, and their applications.

The Process

Gas lines provide critical functions to individual homes and sometimes to entire towns or cities. They must be properly maintained and managed to prevent damage or a loss of service.

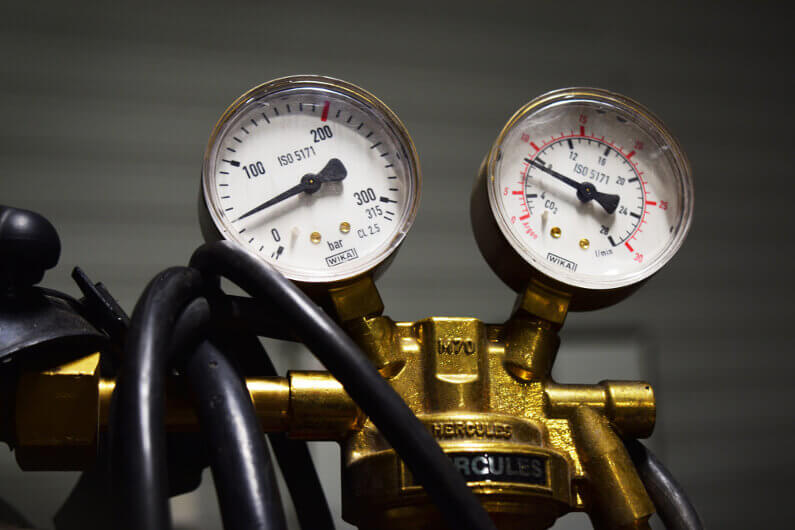

Pressure testing is one of the most common ways of testing a line’s integrity. It involves putting a gas line under extreme pressure to test its pipes, fittings, joints, and other critical components.

The test is performed using pressurized air, gas, or water. Adding an extreme amount of pressure ensures the gas line can withstand whatever functions it must perform throughout its lifetime.

Regulations mandate what levels of pressure must be reached and the materials to use. The regulations depend on the line being tested, the company that the testing professional works for, and other factors.

No matter the process, safety is the top priority when it comes to pressure testing.

Types

There is no single way to perform gas pressure testing, giving professionals a wide variety of options to choose from. All the methods can be grouped into two major types; hydraulic and pneumatic.

Hydraulic pressure testing uses water and occasionally adds a dye to make leaks and other issues easier to see. Pneumatic testing uses air or a non-flammable gas.

Hydraulic testing is safe even in higher-pressure situations. Pneumatic testing is still a popular option and fitting for most low-pressure tests.

Applications

Since the 1970s, it’s become standard practice to perform pressure testing on any new pipeline before it’s installed. This helps professionals remedy any issues before they become unmanageable.

It’s also common to perform gas pressure testing on a line that’s been in use for years. This is a more expensive and time-consuming process, as the lines already contain gas and may be difficult to access. Checking for deterioration and damage as the lines age is critical to everyone’s safety.

Choosing a Gas Pressure Testing Service

Gas in all its forms, especially natural gas, is becoming an increasingly popular option in American homes. Its behavior can be difficult to understand, but knowing a few gas laws and the factors related to them makes it possible.

All gas lines must be maintained and examined regularly. Piping problems can cause a variety of issues including leaks and line damage. Gas pressure testing helps stop these problems before they occur.

Finding the right professionals to deal with this and any other plumbing issues ensures you get the best results. Check out our plumbing repair services and contact us today for more information.

2 Comments

Submit a Comment

Request a Quote Now

suburban plumbing

Full Service Plumbing Orange County, CA.

Suburban Plumbing

14933 Adams Street

Midway City, CA 92655

(714) 922-3555

or Send Us an Email Here.

© 2017-2025 SuburbanPlumbingOC.com

– All rights reserved. –

Information on this website may not be re-used without prior written consent from Suburban Plumbing.

QUICK LINKS

HOME | PLUMBING SERVICES | PLUMBER NEAR ME | REVIEWS | ABOUT | COVID SAFETY | BLOG | COUPONS | CONTACT | SITE MAP

HOURS & LICENSE INFO

Monday-Friday: 8:00am to 7:00pm

Saturday: 8:00am to 5:00pm

Sunday: Closed Normal Appointments

Emergency Client Service Available

California Licensed, Bonded, Insured

C36 Plumbing Contractors License 833520

How long does testing gas pressure last?

I pumped my new gas lines up to 39.5 psi, they lost .5 psi in 20 minutes, is this acceptable or not. 8 days ago I pumped them up to 20 psi, when the inspector came after 8 days the pressure was down around 5 psi, He made me pump them back up to 10 psi, said he could see the pressure dropping, that I had to find the leak. Can’t find a leak anywhere, is he looking for a kickback.